Designing and Building a Component in Metal with Additive Technologies

Date and time

Location

Renishaw

1001 Wesemann Dr. West Dundee, IL 60118Refund Policy

Description

Industrial 3D-Printing, often referred to as Additive Manufacturing (AM), has increasingly become available and enables the cost-efficient production of bionic structures and weight-optimized parts to drive down product weight.

However, often designers and engineers are lacking the necessary background knowledge in the area of topology optimization and design for Additive Manufacturing to fully exploit this potential.

Training attendees will have the opportunity to observe and experiment with the sequences of designing a part in the traditional way and designing a lighter, optimized 3D printed part.

Class Format & Released Material

- The training is composed of 2.5 days

- Instructor-led

- Presentation and hands-on exercises

- One student to a computer

- Timetable: 8.00 AM – 5PM (including lunch, 1 hour)

- Each participant will receive a USB drive or a DVD containing presentations/manuals in PDF format & demo files and an attendance certificate

Potential attendants & Prerequisites:

Potential Users: This hands-on training is aimed towards engineers, designers, and technicians, who have already gained experience with additive manufacturing (functional principle, technology overview). Based on this pre-knowledge this training will provide the necessary steps and tools to come up with a light-weight part design including bionic interpretation, which is manufacturable in additive processes.

Prerequisites: Basic knowledge about CAE/CAD Tools and mechanical design

Agenda

Day 1: 8:00am – 5:00pm:

- Welcome and Introduction (Altair and Renishaw)

- Introduction to Design for Additive Manufacturing (Altair)

- Topology Optimization Theory

- Design guidelines and bionic principles for Additive Manufacturing

- Introduction to additive manufactured part design using simulation software (Altair Inspire)

- Design

- Software Interface

- Geometry Creation and Model Simplification

- Assembly Connections

- Design Space Set-up

- Manufacturing Constraints

- Concept interpretation

- Concept Design

- Manufacturing

- Part orientation

- Support Structures

- Print simulation

- Thermal Distortion

- Residual Stress

- Design

- Are you having trouble strategically identifying which parts are most applicable to the additive process? This discussion will provide insights and approaches on how to screen your current part designs in ultimately maximizing the value and performance of the same part additive manufactured.

Day 2: 8:00am – 5:00pm:

- Finding ideal processing parameters for your AM Parts

- The choice of processing parameters used to melt and solidify the metal powder is fundamental, as the thermal history of the alloy affects both its integrity and its strength. Selecting parameters that suit the material in question and the specific component to be build are critical to the success, particularly in series production applications.

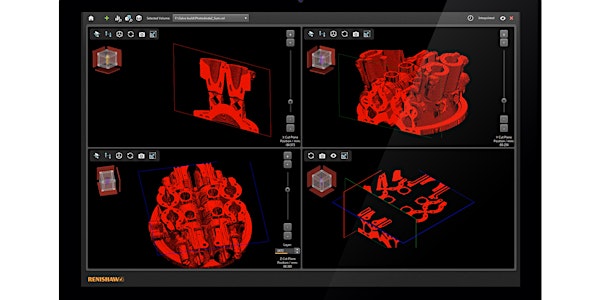

- QuantAM – Parameter Development Overview

- A review of the iterative multi-variate parameter development process. The designed experiment approach to selection of ideal processing parameters.

- Metallographic Practices for AM

- Validation protocols for all experimental work. Moreover, evaluation of secondary post-processing techniques to delivery serial production components fit for functional use.

Day 3: 8:00am – 2:00pm:

- AMPD Operation Technician lead training. Users will understand the common functional and mechanical requirements of the set-up and tear-down of a standard Renishaw machine package. Topics including:

- Machine Function

- Machine Calibration

- Build Plate Preparation

- Machine Cleanliness

- Powder Preparation and Procurement

- Export / Generation of Build Files

- Machine Time Up-keep (InfiniAM Central)

- Process Monitoring

- Applications Eng. Support

- MeltVIEW / LaserVIEW modules

- Standard product validation protocols

- De-build of machine

- Machine Cleaning

- Powder Handling

- Post-Secondary Processing

- Part Cleaning

- EDM / Machining

- AM Manufacturing Workflow / Processing Overview

- Applications Engineer lead discussion. User will learn topics pertaining to manufacturing workflow in conjunction with potential cost applications. Topics to be discussed include:

- Part Positioning on Build Plate

- Support Design / Selection / Necessity

- Cost Modeling Calculations

- General Metallographic Processing Overview

- Product Validation

- Powder to Part

- Applications Engineer lead discussion. User will learn topics pertaining to manufacturing workflow in conjunction with potential cost applications. Topics to be discussed include:

Hotel Recommendations:

- $99/night when you mention you're with Renishaw

Hilton Garden Inn Hoffman Estates

- $101/night when you mention you're with Renishaw - breakfast included

- $99/night when you mention you're with Renishaw and use booking code LRENI - breakfast included

Evening Networking Event:

Join us at Pinstripes on November 8th from 6:30pm-9:30pm for dinner, drinks, bowling and bocce ball.

- Location: 100 W. Higgins Road, South Barrington, IL 60010

- A shuttle bus has been arranged to provide transportation to and from the hotels to Pinstripes

Organized by

As a producer of systems for the additive manufacturing of components in metal and polymers we enable our customers to produce high-quality products based on industrial 3D printing technologies.

With it's innovative manufacturing systems EOS is the global technology and quality leader for high-end solutions in the field of additive manufacturing (AM). Founded in 1989, we are a pioneer and world leader in the field of Direct Metal Laser Sintering (DMLS) and provider of highly productive Additive Manufacturing Systems for plastic materials. Furthermore our customers benefit from deep technical expertise in global service, applications engineering and consultancy.